Getting The Fire Rated Spandrel Panel To Work

Table of ContentsExcitement About Replacement Double Glazing Panels CostConcrete Spandrel Panel Can Be Fun For AnyoneFascination About Curtain Wall Spandrel Panel DetailReplacement Double Glazed Glass Panels Can Be Fun For EveryoneSome Of Replacement Double Glazing Panels PricesIndicators on Aluminium Spandrel Panel You Need To Know

Sometimes, there are concerns connecting to having way too much unrestrained daylight, sometimes referred to as glare. The difficulty is to make every effort for the highest possible visible light transmittance (VT) as well as the most affordable solar warmth gain coefficient (SHGC) while not protecting against the glass from being too reflective when seen from both the exterior as well as the interior, while regulating glare.The systems need to be totally assembled in a manufacturing facility and also shipped to the site for setup on the structure. The systems are put on the floorings, bundled in cages, utilizing the tower crane as well as reduced right into place using a smaller sized crane or raise had by the glazing service provider. The mullion measurements have a tendency to be slightly larger than a stick system due to their open section as contrasted to the tube form of a basic stick curtain wall surface section.

Systems can be assembled in a factory while the structural structure of the structure is being created. Where stick systems need multiple steps to erect as well as seal the wall surface, unitized wall surfaces get here on the website completely assembled enabling the floorings to be shut in quicker (secondary glazing panels). Unitized systems likewise need much less area on website for format thus supplying a benefit for city websites with room restrictions.

The Only Guide to Replacement Double Pane Glass Panels

The interlacing upright mullions will commonly have two interlocking legs. One leg will remain in the plane simply behind the glazing pocket as well as the other at the interior face of the mullions. The interlocking leg in the aircraft of the glazing pocket will certainly be sealed by gaskets and also is the key line of protection against water and also air seepage.

Systems whose linking legs lock likewise compromise the capacity of the system to fit movement. Some unitized designs are delicate to small irregularities in the spacing of surrounding modules; as an example, if the component joints are somewhat out of resistance, gaskets may not be appropriately compressed as well as moisture security may endure.

This is where field labor have to seal between surrounding systems to accomplish a climate limited wall surface. The interlacing legs of the horizontal mullions are the most critical user interface of a unitized system.

Gable Spandrel Panel for Beginners

These upstanding legs have gaskets that secure against the walls of the lower straight. Much more robust systems will certainly supply two upstanding legs with gaskets on both legs.

The stack joint is the straight joint where devices from adjoining floors fulfill. Putting the stack joint at the sill of the vision glass (generally 30" over the flooring) will decrease the measurement of the vertical mullions. This positioning utilizes the back period of the mullion above the anchoring point at the piece to combat the deflection of the mullion below the piece (aluminum spandrel).

Specify that research laboratory examinations are to be performed at an AAMA Accredited Laboratory center. Field Mock-up: For all curtain wall surfaces, stock or custom, call for building and also testing of an area mock-up representative of the wall/window setting up. This is best set up prior to the launch of shop drawings for home window production, to ensure that there is a possibility to make design adjustments based on the examination efficiency of the field mock-up.

Getting My Secondary Glazing Panels To Work

The details linked with this section of the BEDG on the WBDG were created by committee and are planned entirely as a method to show basic design and building principles only. Ideal usage as well as application of the principles illustrated in these details will certainly differ based on efficiency factors to consider as well as ecological conditions special to each project and, consequently, do not represent the final point of view or suggestion of the writer of each area or the committee participants responsible for the development of the great post to read WBDG.

Continual steel sill flashing at the base of the curtain wall surface shields the wall surface framing below a fantastic read from leak with the drape wall surface. Sill flashing must have upturned end dams and also fully sealed corners. Intermediate straight needs to be wept to the exterior as well as protect against water from draining onto the head of the glazing unit listed below.

How Concrete Spandrel Panel can Save You Time, Stress, and Money.

Gasket elevation ought to match to the drape wall surface layout stress. Exterior cover splice sleeves are set up at the face of the pile joint throughout system area installment. Units are developed and also mounted with horizontal as well as upright clearance voids to enable differential movement and suit construction tolerances. Pressure adjusted rainscreen gaskets create a key climate seal at the face of the unitized vertical stack joint according to the straight rainscreen gasket at the unit sill below.

Spandrel glass adapters are used to minimize the depth of the glazing pocket to accommodate decreased profile of spandrel glass. Spandrel glass adapters ought to websites be fully bedded in sealer and incorporated with glazing pocket corner seals to avoid water leakage from glazing pocket to structure interior. System measurement of breeding head as well as sill extruded profiles enables specified floor to flooring deflection at the stack joint.

Intermediate horizontals quit at the face of the upright system jamb members at each end. Units are hung from the top or face of the nearby floor or building framework making use of mated braces and also area applied bolts with a minimum of clearance for gain access to and assembly. All connections and brackets situated within the units insulated or primary weather seal areas are secured with proper sealer materials throughout area setup.

Get This Report about Insulated Metal Spandrel Panels

non-heat-treated) or completely toughened up glass to continue to be in location until it can be changed. Whether heat-strengthened or totally toughened up, heat-treated glass items are generated in a comparable style as well as utilizing the very same processing tools. The glass is heated up to roughly 650 C (1200 F), then force-cooled to produce surface and also edge compression.

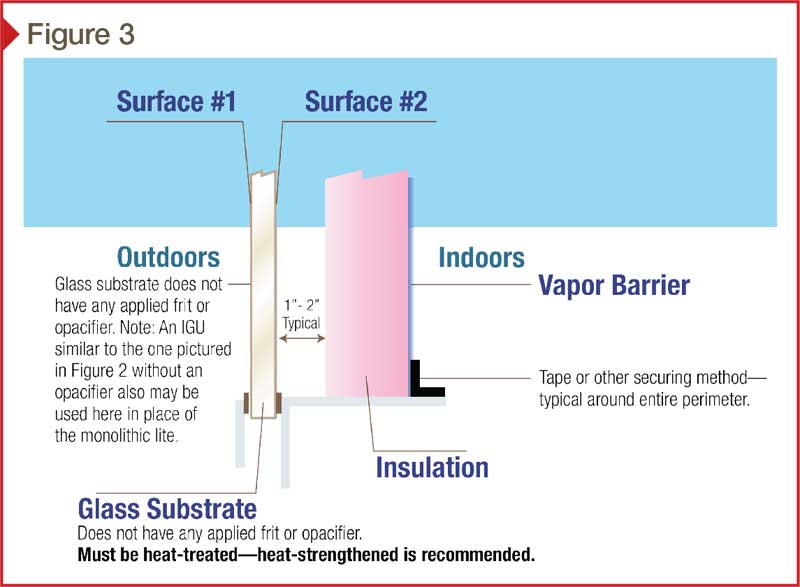

As suggested in Figure 1, insulation is usually utilized together with spandrel glass. When the insulation is to be applied directly to the opacified surface area of the spandrel glass, it is very important to deal with a glass spandrel producer, in addition to the adhesive and also insulation distributors, to make sure these products work with the opacifying material. insulated metal spandrel panels.